Polycarbonate 3d Printing Fumes

Polycarbonate 3d printing can be difficult if you don t take the proper precautions.

Polycarbonate 3d printing fumes. It is also used in electrical and phone casings bike and motorbike helmets and other strong parts like scuba diving masks and even riot shields. It is a good electrical insulator while having heat resistant properties. Editorial content on principle can not be bought or influenced. The gizmo dorks 3d printer polycarbonate filament also known as pc filament is a strong thermoplastic material used in 3d printing.

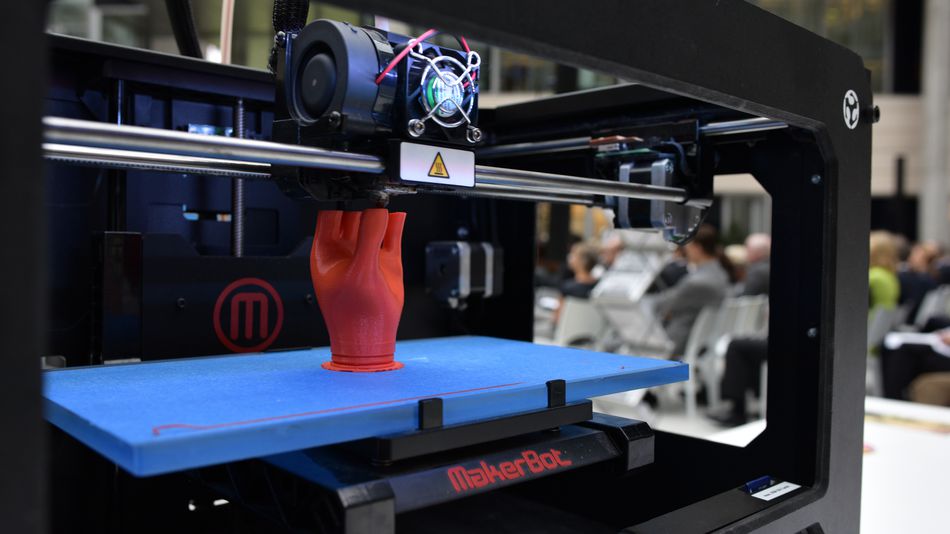

Polycarbonate outside of 3d printing is commonly used in applications that benefit from its transparency such as optical glass and bulletproof glass due to its phenomenal impact resistance. Polycarbonate is used in data storage for compact discs dvd s and blu ray s. Aside from the usual hazards of working with electronics and components that can be heated to more than 200 c the fumes generated by heating the plastic filaments have always been a cause of concern for 3d printing professionals. This makes a heated bed essential.

The bed should ideally be between 135 and 150 c. Polycarbonate also denoted as pc is a strong durable and tough material. It s a naturally transparent thermoplastic with high impact resistance and excellent heat resistance. Although 3d printing in your workshop or office seems like a benign activity there are still some hazards you should watch out for.

These tips will help you reduce the chances of common 3d printing issues associated with polycarbonate such as warping stringing and oozing. When printing polycarbonate and polyetherimide i stay out of the room completely and wait for all of the air in the room to clear out before coming back in. Use a proper build surface adjust settings to prevent stringing and oozing customize first layer settings. Pc fumes are potentially nasty since there s some unknown but possibly meaningful quantity of bpa and i like to play it safe with whatever burns at pei temperatures 350c even with.

3d printers can often run overnight or for long hours as it prints a model layer by layer. It is easily extruded using common extruder drive systems with all metal hotends. To limit problems with bed adhesion and warping formulations adapted to printing may be used. Polycarbonate filament has many uses in everyday applications.

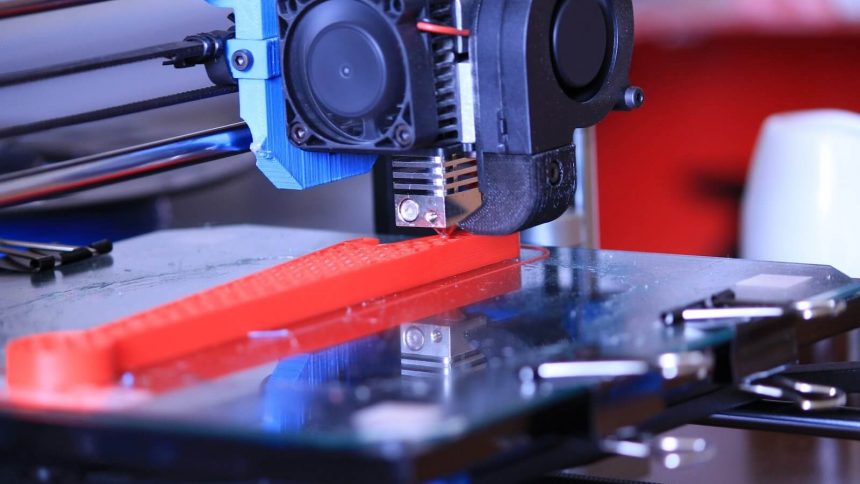

As such this material needs high temperatures in order to extrude and have proper layer adhesion. As a 3d printing filament it s heat resistance is both a benefit and a problematic characteristic as it is even more prone to warping and splitting than abs filament. One big health and safety concern related to the use of 3d printers is the fumes that get emitted when plastic or any other material from the filament reel gets melted by the printer. To keep all3dp free and independent we finance ourselves through advertising and affiliate revenues.