Plastic Astm Standard Tensile Test Specimen Dimensions

D5947 test methods for physical dimensions of solid plastics specimens.

Plastic astm standard tensile test specimen dimensions. D638 test method for tensile properties of plastics. D638 test method for tensile properties of plastics. D4000 classification system for specifying plastic materials. Though astm d638 measures many different tensile properties the following are the.

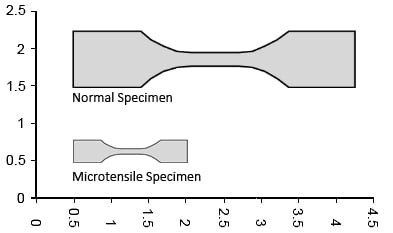

However for testing specimens in the form of thin sheeting including film less than 1 0 mm 0 04 in in thickness astm standard d882 is the preferred test method. This test method uses standard dumbell or dogbone shaped specimens under 14mm of thickness. Elongation tensile strength elongation and reduction of area. A 50 mm gauge length is recommended.

D6287 practice for cutting film and sheeting test. 1 2 the gauge lengths for most round specimens are re quired to be 4d for e8 and 5d for e8m. D5947 test methods for physical dimensions of solid. 5 1 the property k ic g ic determined by these test methods characterizes the resistance of a material to fracture in a neutral environment in the presence of a sharp crack under severe tensile constraint such that the state of stress near the crack front approaches plane strain and the crack tip plastic or non linear viscoelastic region is small compared with the crack size and specimen.

D882 test method for tensile properties of thin plastic sheeting. Standard test method for tensile impact energy to break plastics and electrical insulating materials. Gauge length changes with astm e83 class b 2 accuracy. Astm d638 is one of the most common plastic strength specifications and covers the tensile properties of unreinforced and reinforced plastics.

Astm d638 is performed by applying a tensile force to a sample specimen and measuring various properties of the specimen under stress. D883 terminology relating to plastics. It is conducted on a universal testing machine also called a tensile testing machine at tensile rates ranging from 1 to 500 mm min until the specimen fails yields or breaks. D618 practice for conditioning plastics for testing.

D883 terminology relating to plastics. Test specimens made from powder metallurgy p m materials are exempt from this requirement by industry. D4000 classification system for specifying plastic materials. D618 practice for conditioning plastics for testing.

Standard test method for indentation hardness of rigid plastics by means of a barcol impressor. A universal testing machine tensile testing machine is needed to perform this test. An absolute accuracy of 10 μm for a 50 mm gauge length and relative accuracy within 0 5 are required by astm d638 for measuring the tensile modulus of elasticity. The gauge length is the most significant difference between e8 and e8m test specimens.