Powdered Iron Core Inductor Calculator

Iron powder core inductors.

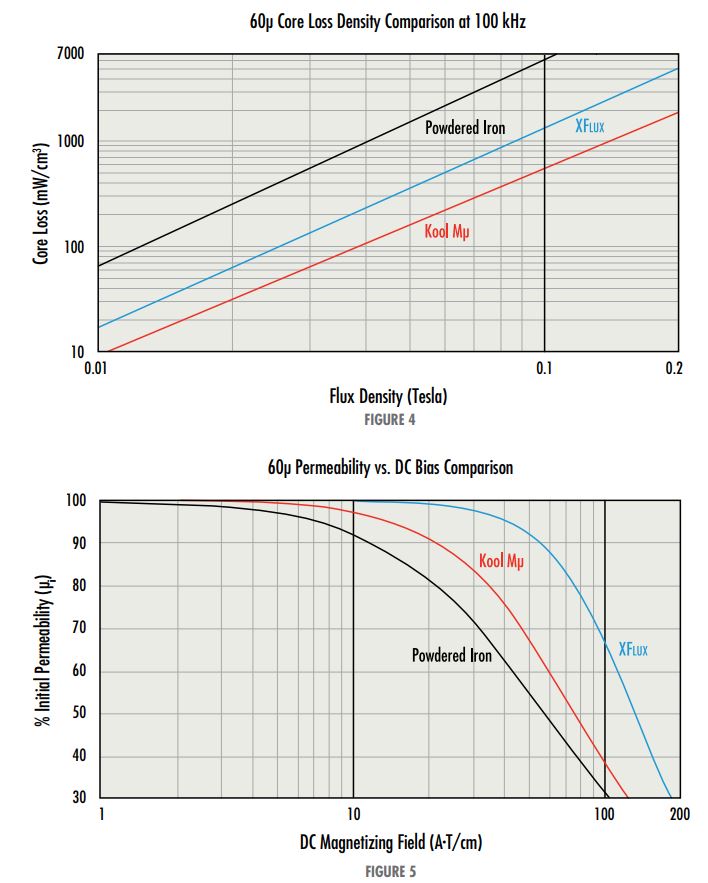

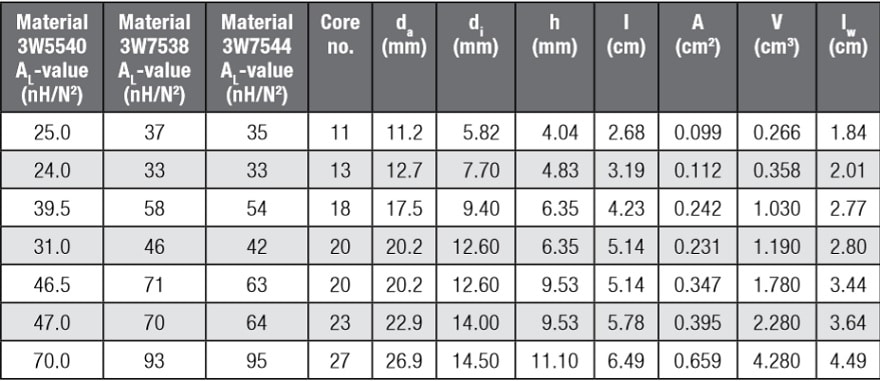

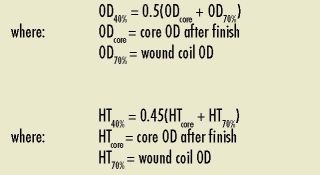

Powdered iron core inductor calculator. Determine core size and number of turns to meet the following requirement. Powder core solutions for next gen communications. Design options for this core are to consider a larger core a lower permeability material a lower loss material or some combination of these three. The calculators are based on operation in the continuous conduction mode only information determined in the discontinuous conduction mode.

The core of such kind of inductors is made up of a mixture of iron grains with an organic binder such as epoxy resin etc. First select the core material type. The inductor is a common school use transformer 5000 turn coil with wire diameter about 0 15mm the official air core value is 0 6h however when i calculate the iron core got a result of 105h. To use the calculator.

Hello sir do you think a 100 henries inductor coil normal. Iron powder cores are distributed air gap cores that are primarily used in power inductor applications. Micrometals alloy powder cores are becomming increasingly popular for emerging applications in 5g hardware and power systems due to their high efficiency and reliability. A minimum inductance with dc bias of 0 6 mh 600 uh b dc current of 5 0 a.

Could this be possible. Our optimized alloys like oc and od are formulated specifically to deliver exceptional dc bias or core loss performance. The epoxy insulation coating over the iron particles reduces the eddy current loss in the core. Power transformer design.

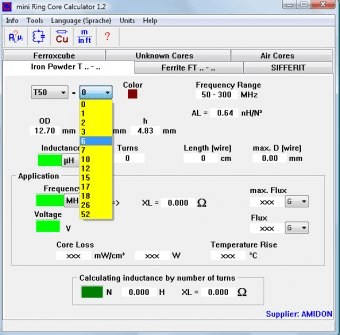

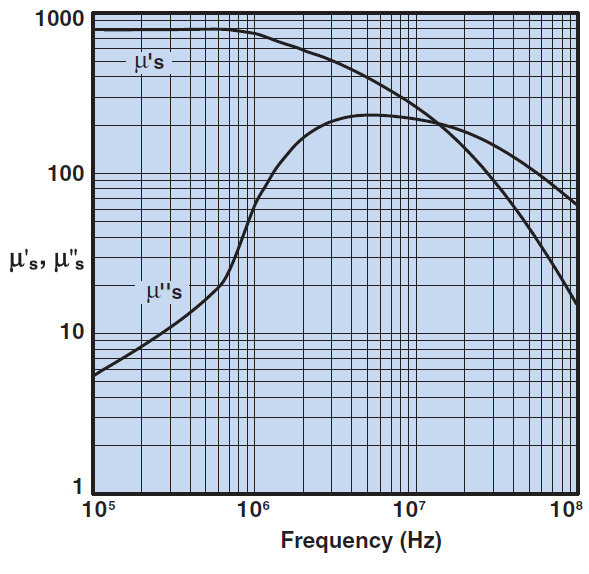

Table 2 give interpolated values for µ and µ for some common mixes at spot frequencies in the hf ham bands. Coplanar waveguide impedance calculator. Core selection example. Iron powder toroidal coil amidon ferrite toroidal coil amidon broadband impedance matching with transformer.

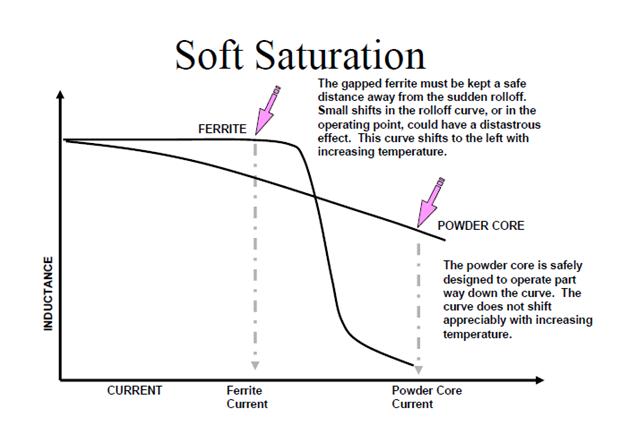

Amidon iron powder toroids calculator. The maximum peak current should be kept below the i sat value of the selected inductor although it can be exceeded with caution due to the soft saturation characteristics of the powdered iron core material. Powder core materials are high resistivity low hysteresis and eddy current losses and excellent inductance stability under both dc and ac conditions. Ei m core.

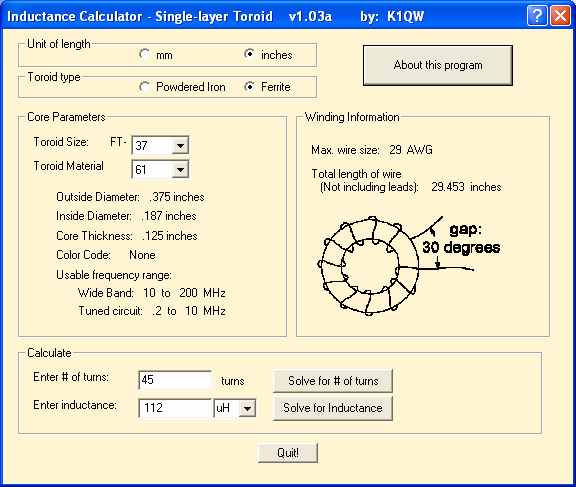

Toroid coil winding calculator use this online tool to calculate the number of winding turns required to achieve the desired inductance with ferrite and iron powder toroidal cores. If the peak inductor current is less than 20 a the ferrite core is likely to be preferred core choice whereas the powdered iron core would be preferred at higher peak currents. The calculator can be applied to powdered iron cores but differently to ferrite the complex permeability is not usually published enter it as zero and r cannot be calculated and µ tends to be less frequency sensitive at hf than most ferrite mixes.