Plate Type Heat Exchanger Parts And Functions

Figure 4 heat transfer in a double pipe heat exchanger.

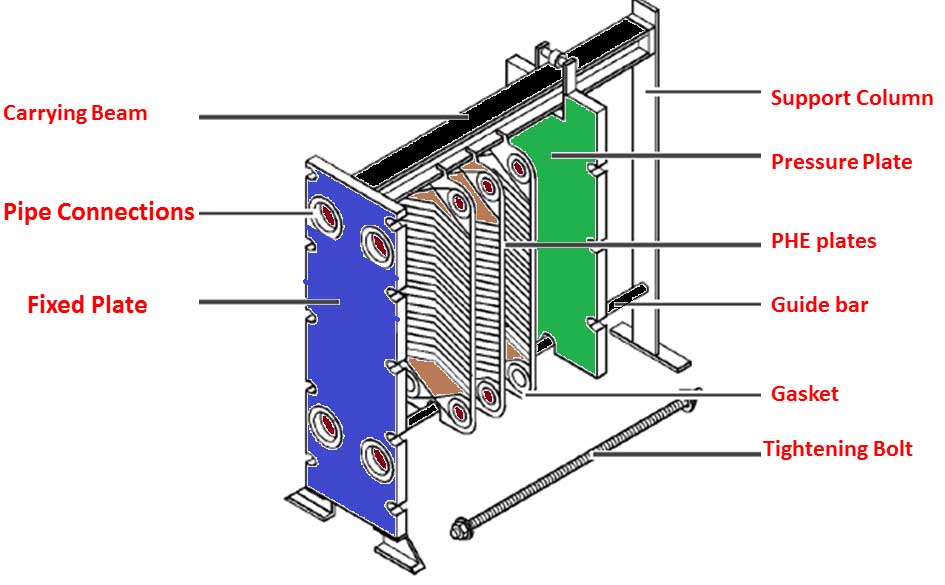

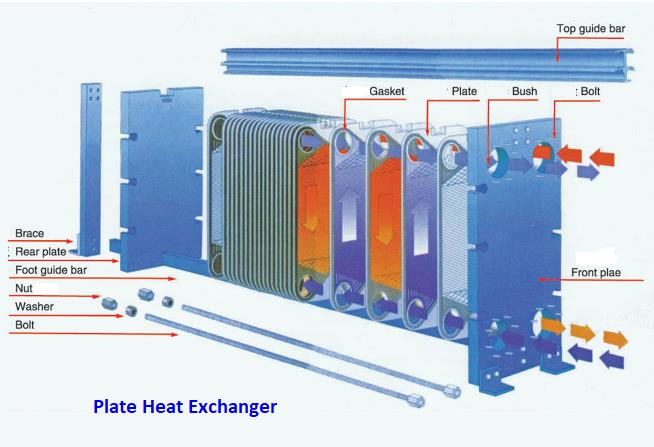

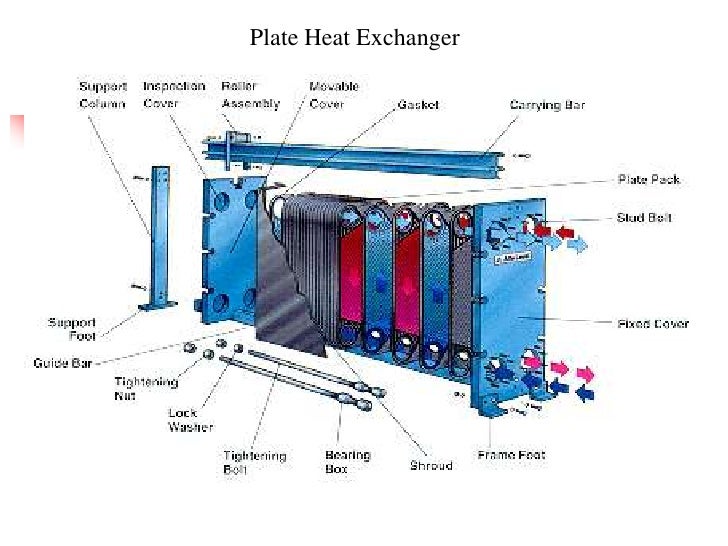

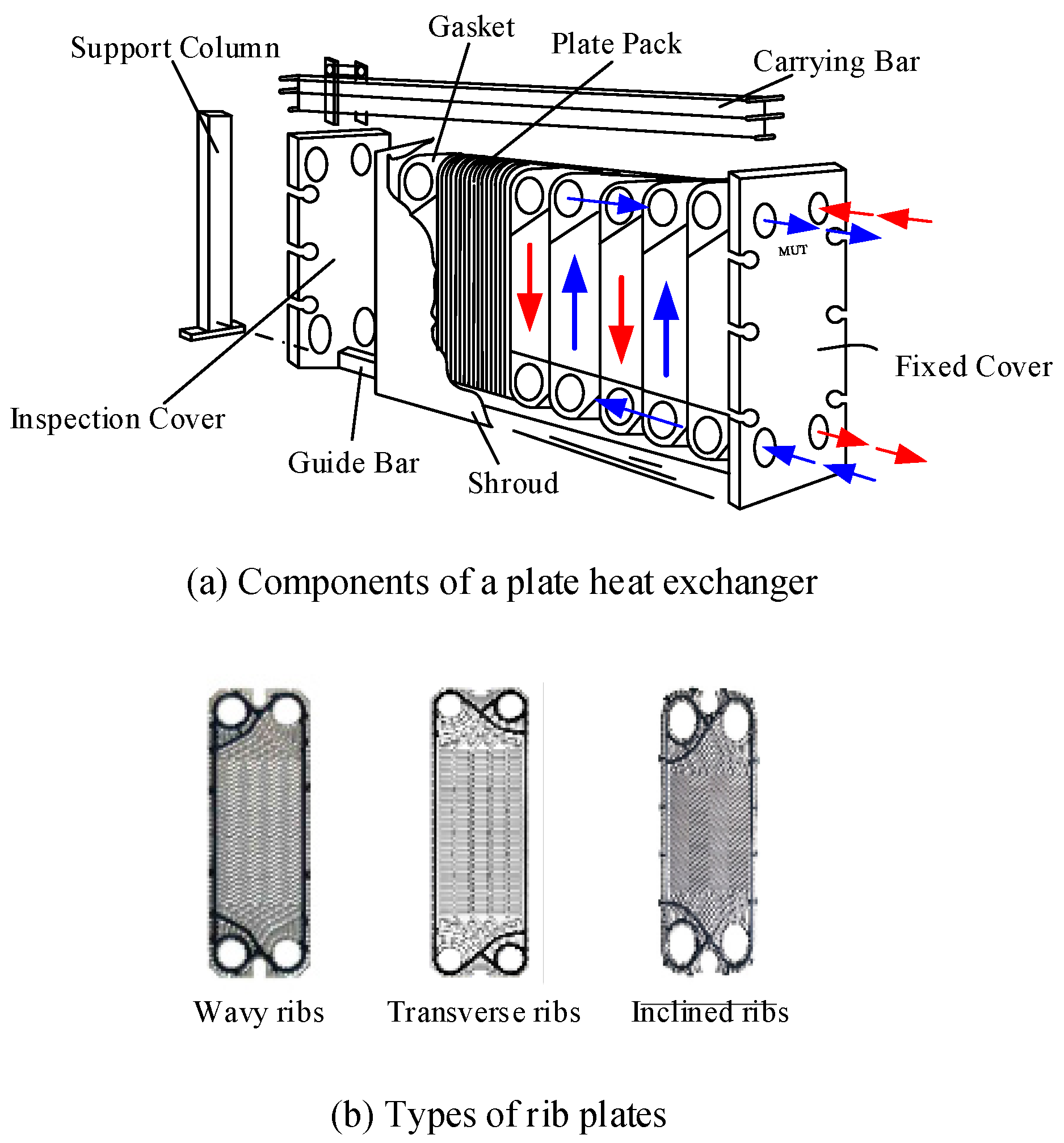

Plate type heat exchanger parts and functions. In heat exchangers there are. The basic concept of a plate and frame heat exchanger is two liquids flowing on either side of a thin corrugated metal plate so heat may be easily transferred between the two. Plate type heat exchanger consists of plates instead of tubes to separate the hot and cold fluids. Disclaimer of trademark usage spares parts supplied by marine technical group ltd.

This facilitates the transfer of heat and greatly increases the speed of the temperature change. Included are accessories for worker and workplace protection collection of process data effective cleaning replacement gaskets and trouble free unit opening and closing. For plate and frame heat exchangers tranter offers practical upgrades for safety efficiency easier maintenance and lower cost operation over long life cycles. On the other hand according to their type of construction exchangers are classified as.

They are widely used in space heating refrigeration air conditioning power stations chemical plants petrochemical plants petroleum refineries natural. A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids this has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids are spread out over the plates. A heat exchanger is a system used to transfer heat between two or more fluids heat exchangers are used in both cooling and heating processes. Examples of this type of heat exchanger are shell and tube exchangers double tube exchangers and plate heat exchangers.

Baffles direct the flow of fluid between plates. Plate type heat exchanger 1. In multi tubular or shell and tube heat exchangers it is usual to combine. Introduction a heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another.

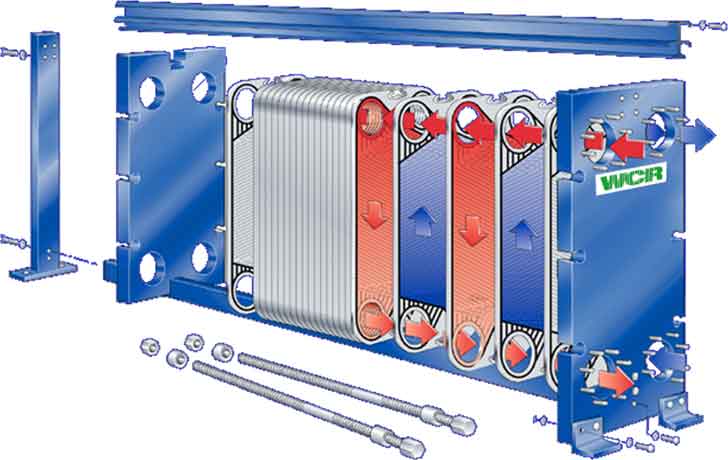

A plate heat exchanger is a unit which transfers heat continuously from one media to another media without adding energy to the process. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. Because each of the plates has a very large surface area the plates provide each of the fluids with an extremely large heat transfer area. A plate exchanger consists of a series of parallel plates that are placed one above the other so as to allow the formation of a series of channels for fluids to flow between them.

The hot and cold fluids alternate between each of the plates. Also referred to as plate type heat exchangers plate heat exchangers are constructed of several thin corrugated plates bundled together. Maritech and its all associated companies are equivalent fully interchangeable spares for heat exchangers fresh water generators pumps separators heaters and genuine makers types are used only for cross reference unless otherwise stated. Each pair of plates creates a channel through which one fluid can flow and the pairs are stacked and attached via bolting.

They are widely used in space heating refrigeration air conditioning power plants chemical plants petrochemical plants petroleum refineries natural gas processing and sewage treatment. Plate heat exchangers.