Plate Type Heat Exchanger Design Code

1 2 example for estimate vapour flow rate requirement to achieve required outlet temperature of the cold fluid.

Plate type heat exchanger design code. I found the code case 2766 it does not require any design calculations or proof testing for establishing the mawp for gasketed plate packs provided all 6 conditions of cc2766 are met. The pressure drop is an important parameter that needs to be considered in the design and optimization of a plate heat exchanger. The choice of shell and tube type is determined chiefly by factors such as the need for the provision for differential movement between shell and tubes the design pressure the design temperature and the fouling nature of the fluids rather than the function. Liquid to liquid heat exchangers was developed for plate and frame heat exchangers because many applications in commercial hvac systems were designed with very.

For horizontal or flat positions using refrigerant steam any liquids or any gases. Your particular jurisdiction may have other rules beyond asme that will require a plate type exchanger to be designed fabricated and certified to some other code or standard. 1 4 example for plate type heat exchanger heat transfer area calculation. Other codes or standards may apply to things not within the scope of asme viii.

In any process it should be kept as close as possible to the design value with a tolerance range established according to the available pumping power. Mawp of other pressure retaining parts will govern the design. The codes cover all aspects of the construction of heat exchangers except the types of service loads other than pressure and the thermal design. Access the url below and click on the web simulator icon.

These panels can be banked. 1 3 online steam table for saturated steam. Heat transfer equipment may be designated by type or function it performs such as chiller condenser cooler reboiler etc. Hisaka web simulator hws plate heat exchanger this is the rst plate heat exchanger design website opened on the internet in the world.

Cc 2766 is not covering fully brazed or fully welded plate packs. The manufacturer or his agent must be registered with the national board. 1 1 example for finding cold fluid outlet temperature. Plate heat exchangers.

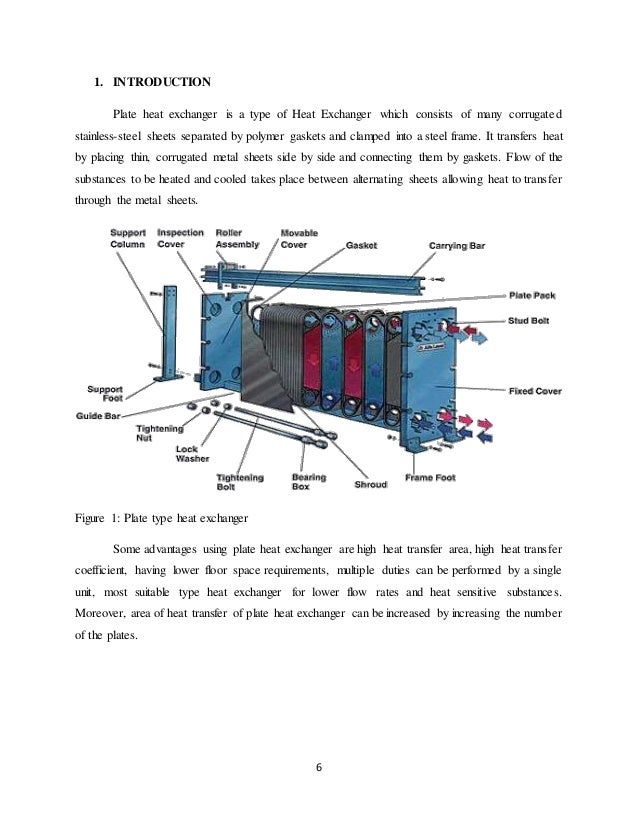

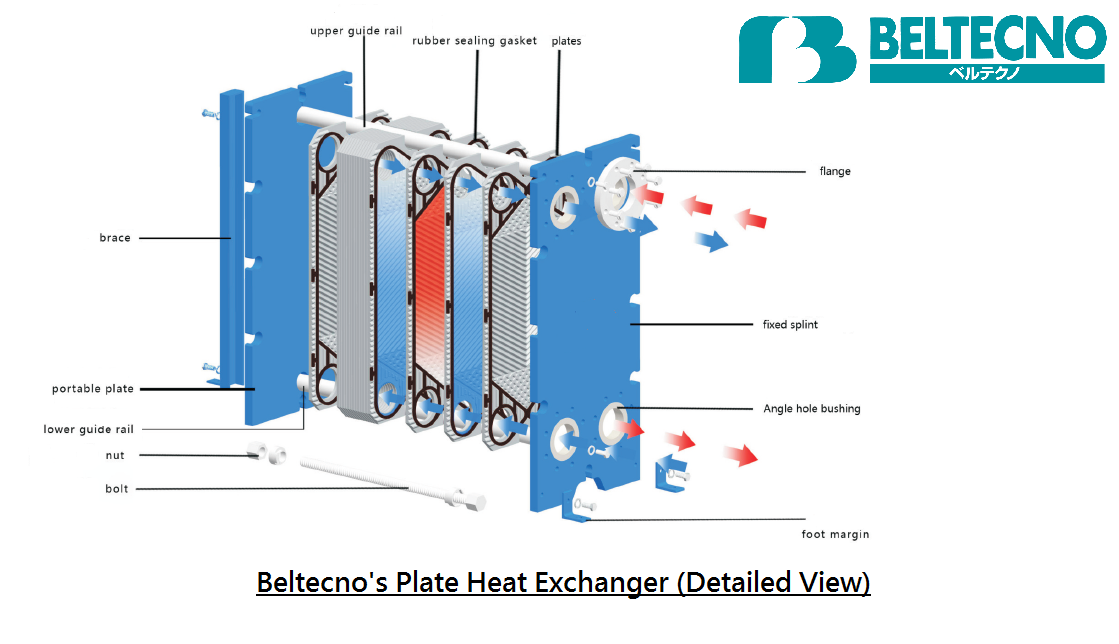

Ahri 400 2001 with addenda 1 and 2. Pressure drop in a plate heat exchanger. You can simulate the plate heat exchanger perfect for your needs any time of the day from anywhere. A plate exchanger consists of a series of parallel plates that are placed one above the other so as to allow the formation of a series of channels for fluids to flow between them.

Design pressure and maximum working temperatures shall be in accordance with project plans. Also available in two pass design allowing vertical position for liquids and in two pass design allowing vertical position for liquids and gases.