Plate Heat Exchanger Calculation Xls

Returns 5 802 psi ft2 actual.

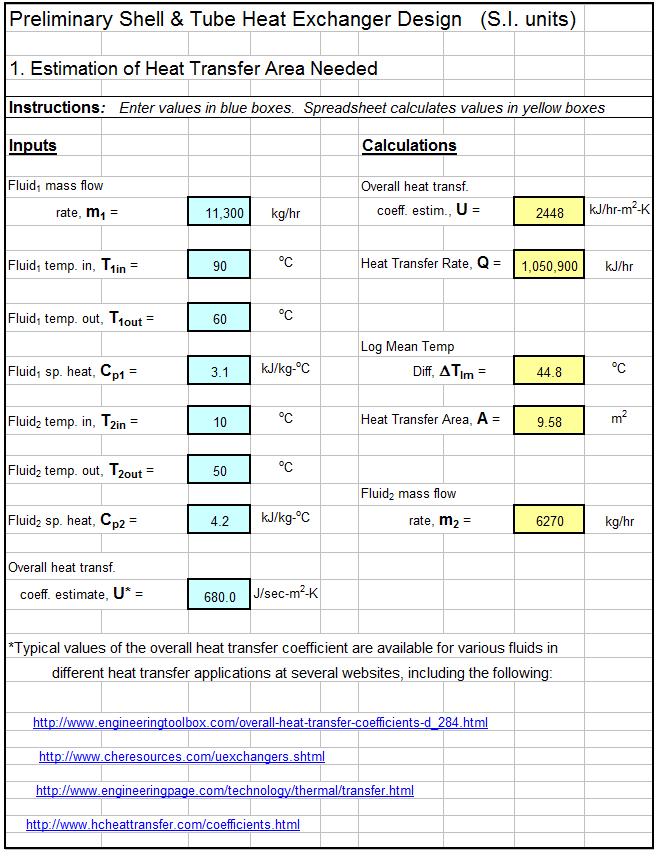

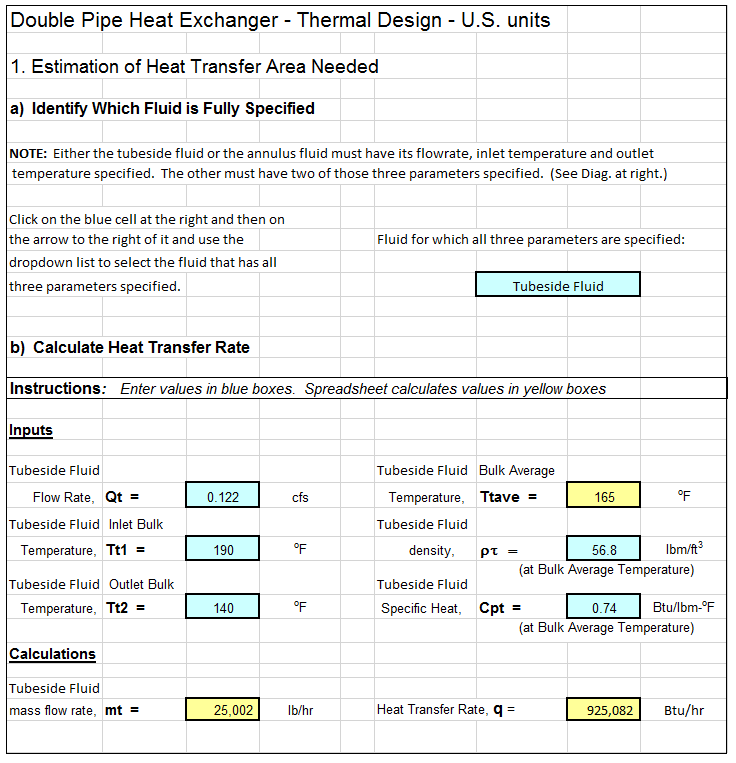

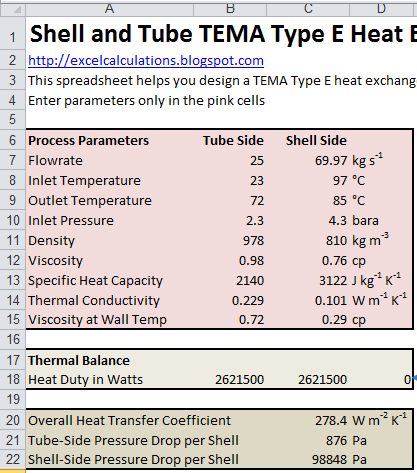

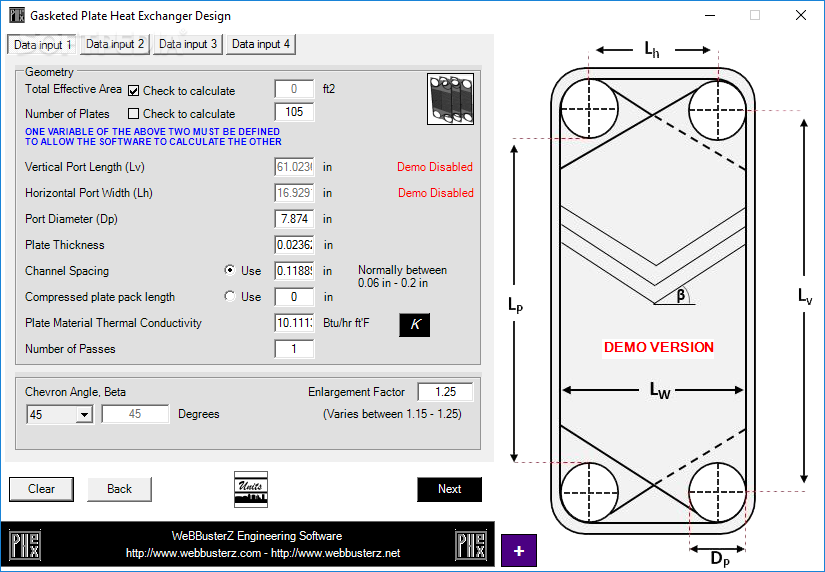

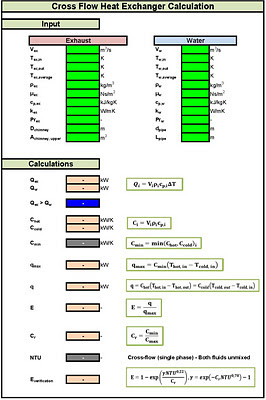

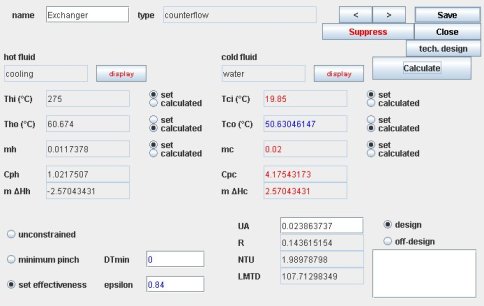

Plate heat exchanger calculation xls. Complete design of plate heat exchanger made in excel. Calculate outlet temperature for hot and cold stream for given flowrates inlet temperature specific heat area of the exchanger and overall heat transfer coefficient u exchanger type heat exchanger area a m. The equations are derived. An excel spreadsheet using the equations developed in this article is also provided.

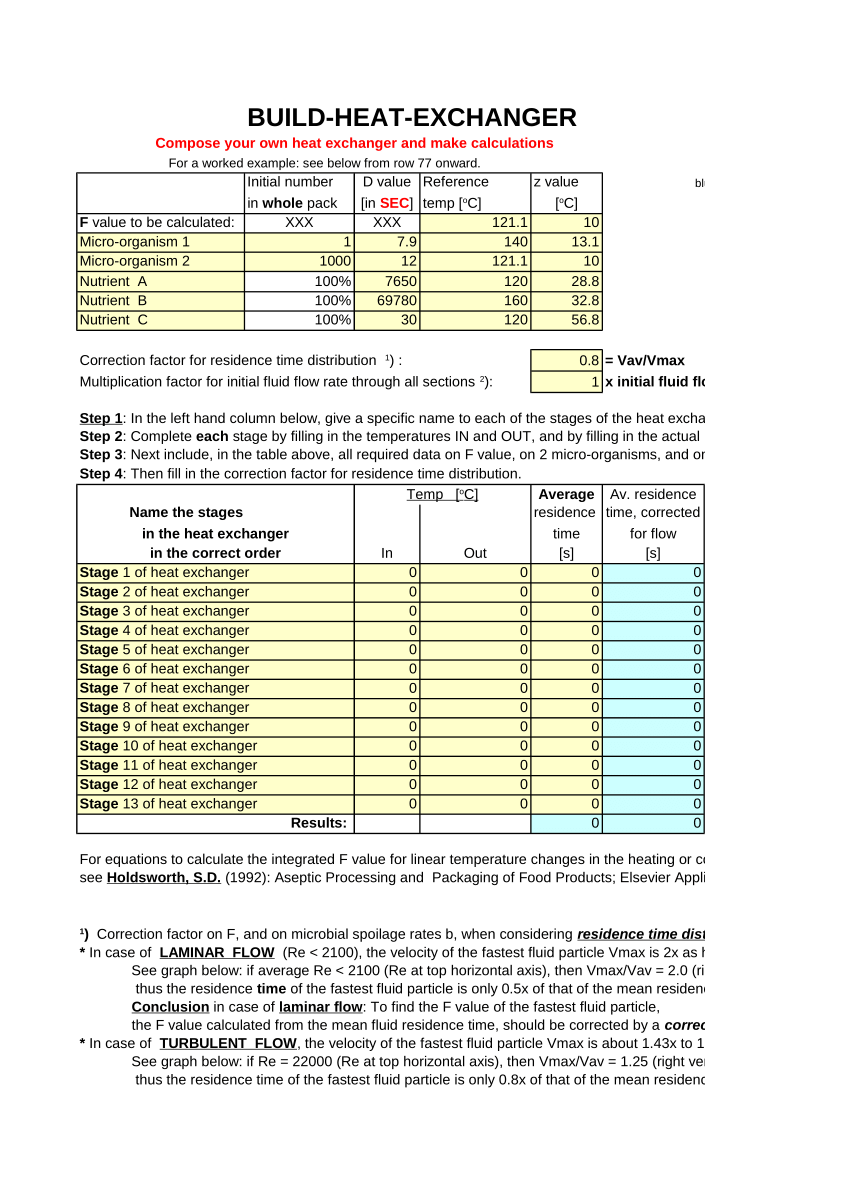

In practice all the thermal duty of the hot fluid fc is transferred to the cold fluid ff thereby fulfilling the next energy balance. Definition of the process for the calculation of heat exchangers. The iterative heat exchanger design process requires an initial rough estimate in order to be able to calculate an initial estimate of the needed heat transfer area. To solve a thermal problem we need to know several parameters.

These templates use s i. It has never been easier. Hexact heat exchanger design software. The amount of heat to be transferred heat load the inlet and outlet temperatures on the primary and secondary sides.

The six most important parameters include. Excel calculations free chemical and petroleum engineering spreadsheets. Ustart 10 btu hft2of over all heat transfer coefficient uo 9 7 btu hft2of ft2 then the required transfer a 63 number of tubes required 239 reset tubes pass step 3 then no. The thermal duty of a fluid in liquid state depends on the mass flowrate and the.

The limitation in the use of the gasketed plate heat exchanger lies in the operating temperature range of the gaskets which places a restriction on the steam pressure that may be used on these units. This allows choice of a preliminary heat exchanger configuration. They will also calculate the number of tubes needed for a shell and tube heat exchanger and to calculate the pipe length needed for a double pipe heat exchanger. Or s i units from this article.

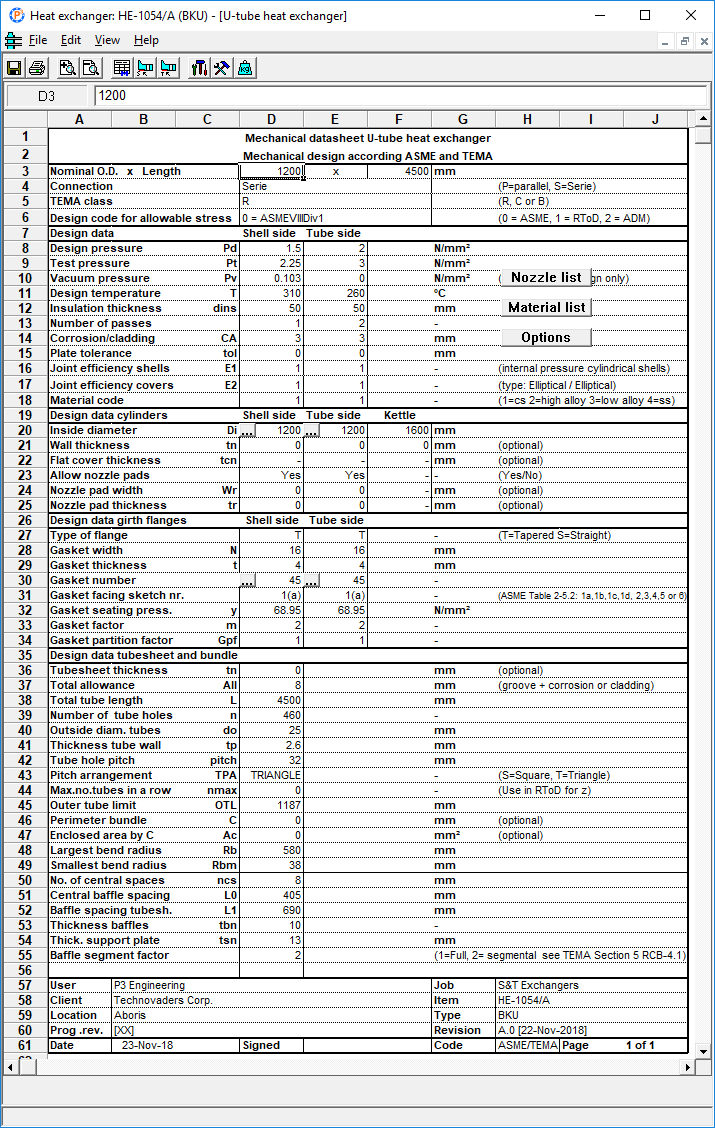

Preliminary heat exchanger design introduction this article will help you understand how you can estimate the initial design characteristics of a heat exchanger. Of passes 2 total tube count 132 tubeside dp incl. Plate heat exchanger calculation method. Download the excel spreadsheet templates in this article to make preliminary heat exchanger design calculations.

Further data can then be determined. Plate heat exchanger design in excel free download as excel spreadsheet xls pdf file pdf text file txt or read online for free. Do you have a need for calculating plate heat exchangers. A heat exchanger is an energy exchange system in the form of heat between a hot and a cold fluid.

In a brazed plate heat exchanger all the plates are brazed together normally using copper or nickel in a vacuum. Heat transfer coefficient u kcal h m c. Brazed plate heat exchangers. Calculate the required heat transfer area based on values needed.