Plastic Injection Molding Cost Examples

See below for some plastic injection molding cost examples.

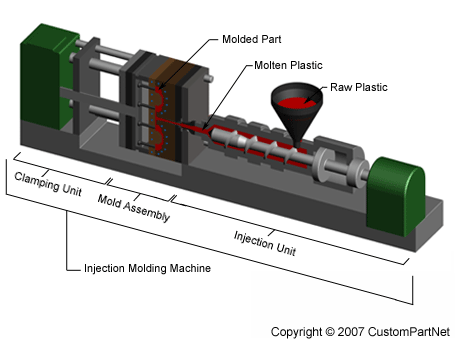

Plastic injection molding cost examples. Injection molding material cost. The injection molding cost examples are categorized by type rapid prototyping insert tooling high production tooling and degree of difficulty basic intermediate advanced. Small parts tend to cost cheaper than a 5 kg piece due to the required material and the machine use. This gas stretches it out into a brand new mold.

Blow molding is regularly used for bottles and all sorts of other plastic products. Actual costs may vary based on the specific manufacturer equipment geographical location and prevailing. While injection molding may seem costly compared to processes like cnc machining and 3d printing the ability to scale and manufacture thousands of parts makes it a cost effective solution for mass production. Although there are certain factors that can drive the cost of injection molding up or down if you begin with the right formula to calculate the cost per part you may be able to make adjustments that will lower that.

The hourly rate is proportional to the size of the injection moulding machine being used so it is important to understand how the part design affects machine selection. A message was added to the front of the comb at no additional cost. Last updated on april 23 2020. The above cost analysis uses data based on industry averages and typical manufacturing practices and should therefore be viewed only as a guide.

Contact rex plastics to discuss your plastic injection mold needs. The best way to figure out how much you can save with injection molding services over other manufacturing methods is to compute the cost per part. Second the injection molding production cost is primarily calculated from the hourly rate and the cycle time. In terms of cost blow molding is comparably cheap.

Material selection is another consideration in determining what plastic injection molds cost. Plastic injection molding or thermoforming are used to move a hot component to a separate tool that transmits gas to the center portion. It s a lot like asking how much is a house are you looking for a starter home with 1 bedroom and 1 bathroom for you and your cat or are you looking for a 4 bedroom 3 bathroom split level house on 2 acres with a detached 3 car. Very large or complex molds may cost as much as 80 000 or more.

Epsilon industries the injection molding company. The main determinant of molding cost is the amount of. Asking for the cost of a plastic injection mold isn t an easy question to answer but it s the most important one when starting the manufacturing process. A small single cavity plastic injection mold usually costs between 1 000 and 5 000.

Injection molding machines are typically referred to by the tonnage of the clamping force they provide. On average a typical mold costs 12 000.