Pcb Panel Design Rules

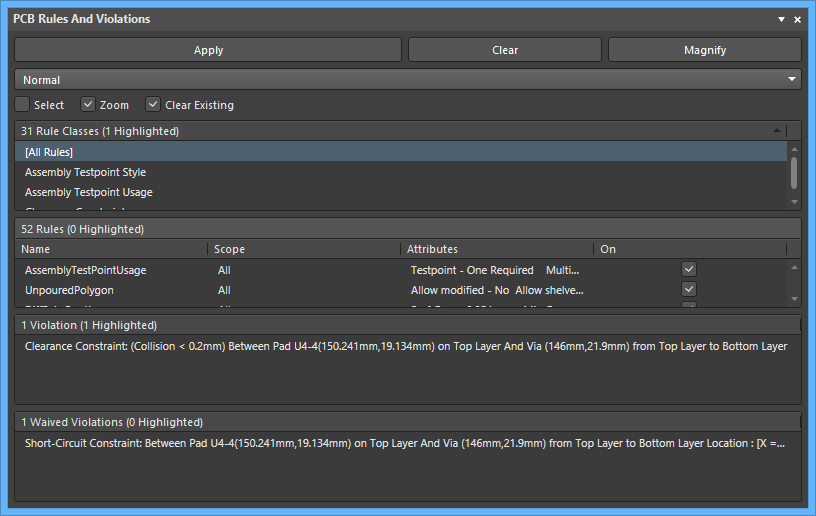

Potentially every pin on the microcomputer can be a problem.

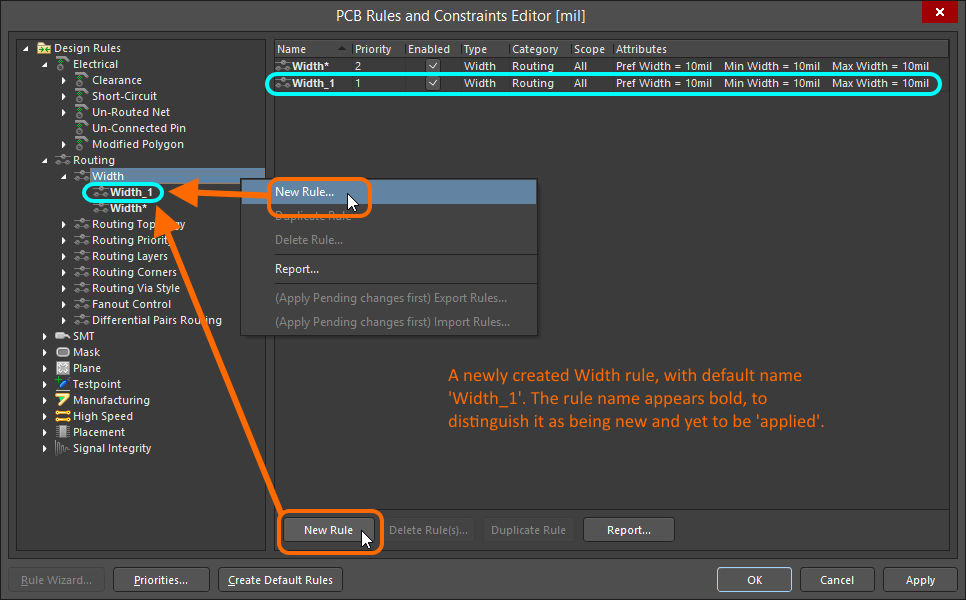

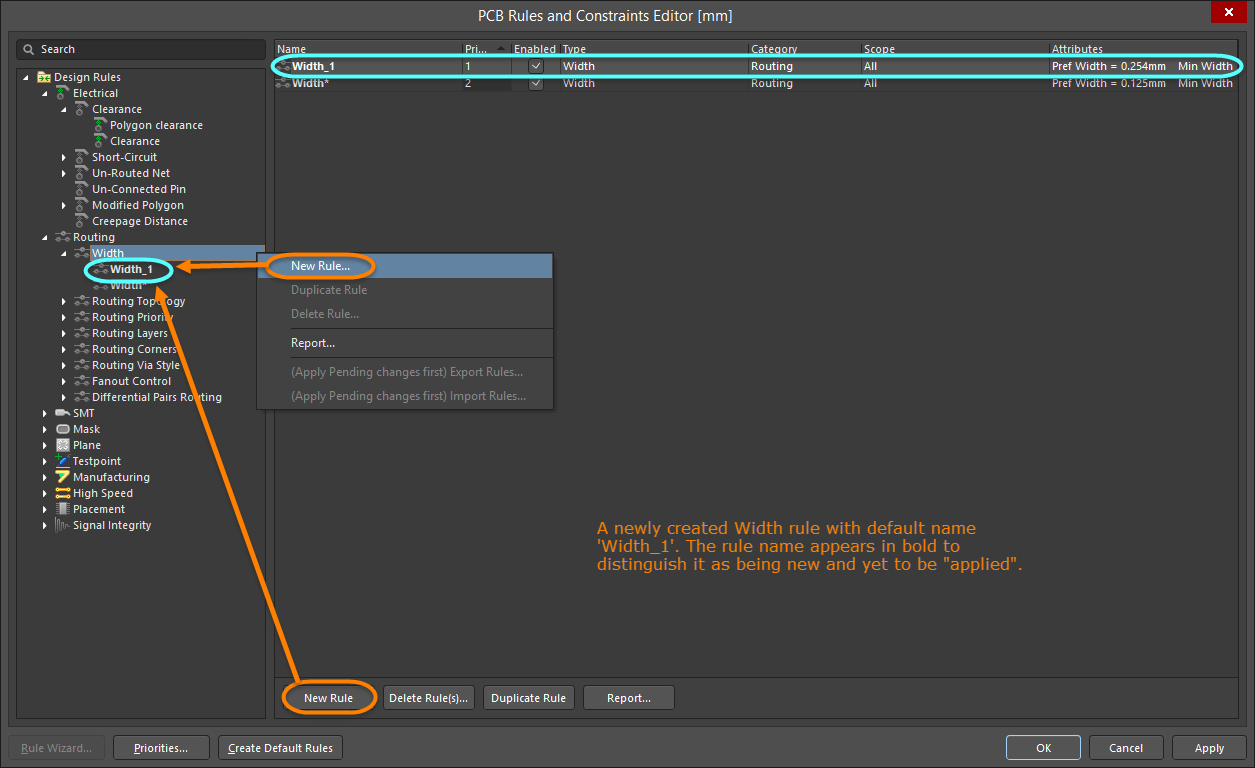

Pcb panel design rules. These guidelines set out best practice to reduce the cost of your boards and to minimize the risk of errors arising during manufacture. Typical when a hardware designer a pcb he considers the electrical signal and the layout of the components on the circuit board focusing on the function of the product. Routed panels with different pcb composed. So if you want to separate multiple boards with v cut or milled slots please make sure each sub board is the same and less than 40 pieces sub boards per panel otherwise there may be extra processing charges.

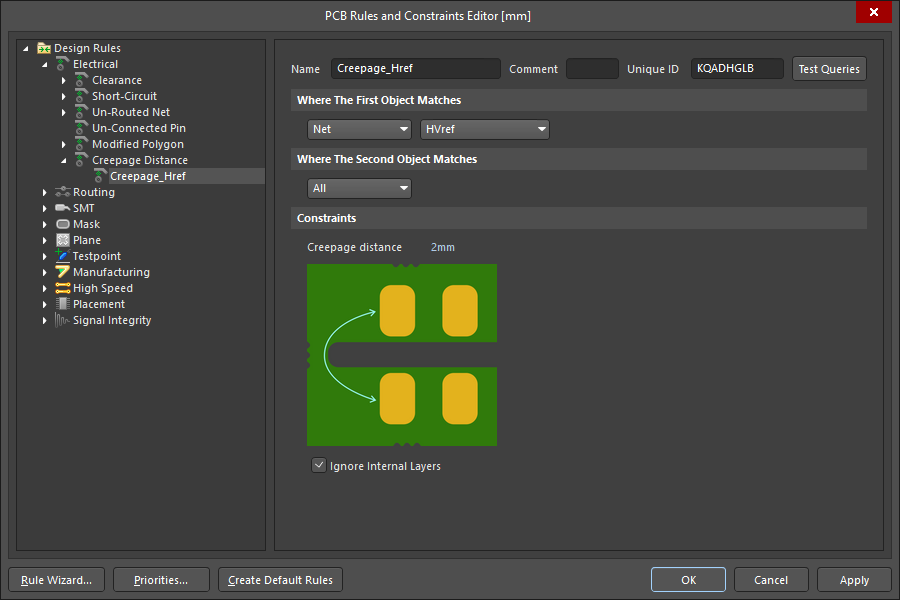

Look at our services overview to see more details. Design guidelines to be discussed concern radio frequency rf noise from the microcomputer. In very complex boards for specialized applications. Not all possible pcb design features are available on all our services.

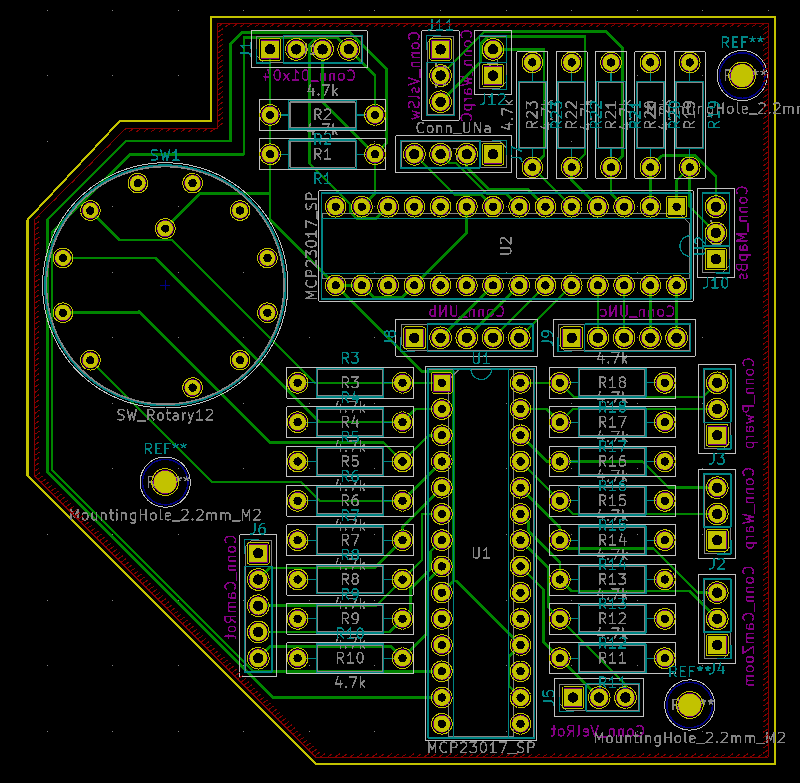

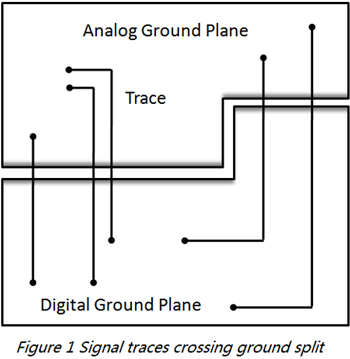

Pcb panel is a combination of several pcb unit boards with various possible connection modes as shown in the figures below. Mechanical processing and design parameters. The noise is present on all outputs inputs power supply and ground at all times. This noise is generated inside the device and is coupled out in many different possible ways.

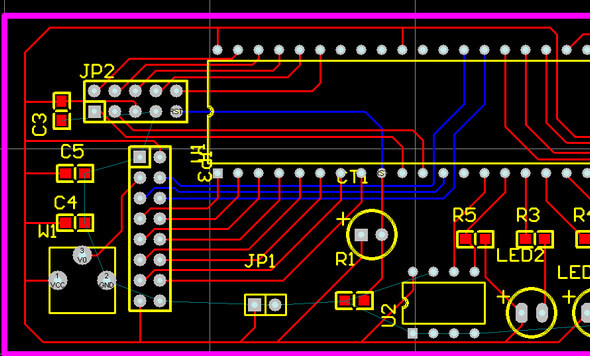

Automated circuit board assembly equipment often has trouble working with smaller boards resulting in more frequent defects during the assembly process to minimize these defects and improve the throughput of the manufacturing process many companies use a process called panelization resulting in a pcb panel. Printed circuit board design rules and pcb layout guidelines become more complex as the number of layers in your stackup increases. Scoring is the preferred choice for two reasons. Not all possible pcb design features are available on all our services.

To satisfy a variety of assembly shops and pcb construction technologies the pcb design has to be more robust stronger panels more clearance of all types more robust board finishes etc. A mix panel scored and routed with different pcbs. Tn004 pcb panel design guidelines tn004 issue 6 12 july 2013 www norcott co uk 7 if a regular shaped pcb is not being panellised provision needs to be made along the longest edges of the pcb for it to be held in the smt assembly equipment. No components tracking or other mechanical feature must come within 0 200 5 00 of the edge of the pcb.

Pcb panel guidelines these guidelines set out best practice to reduce the cost of your boards and to minimize the risk of errors arising during manufacture.