Pcb Fabrication Notes Pdf

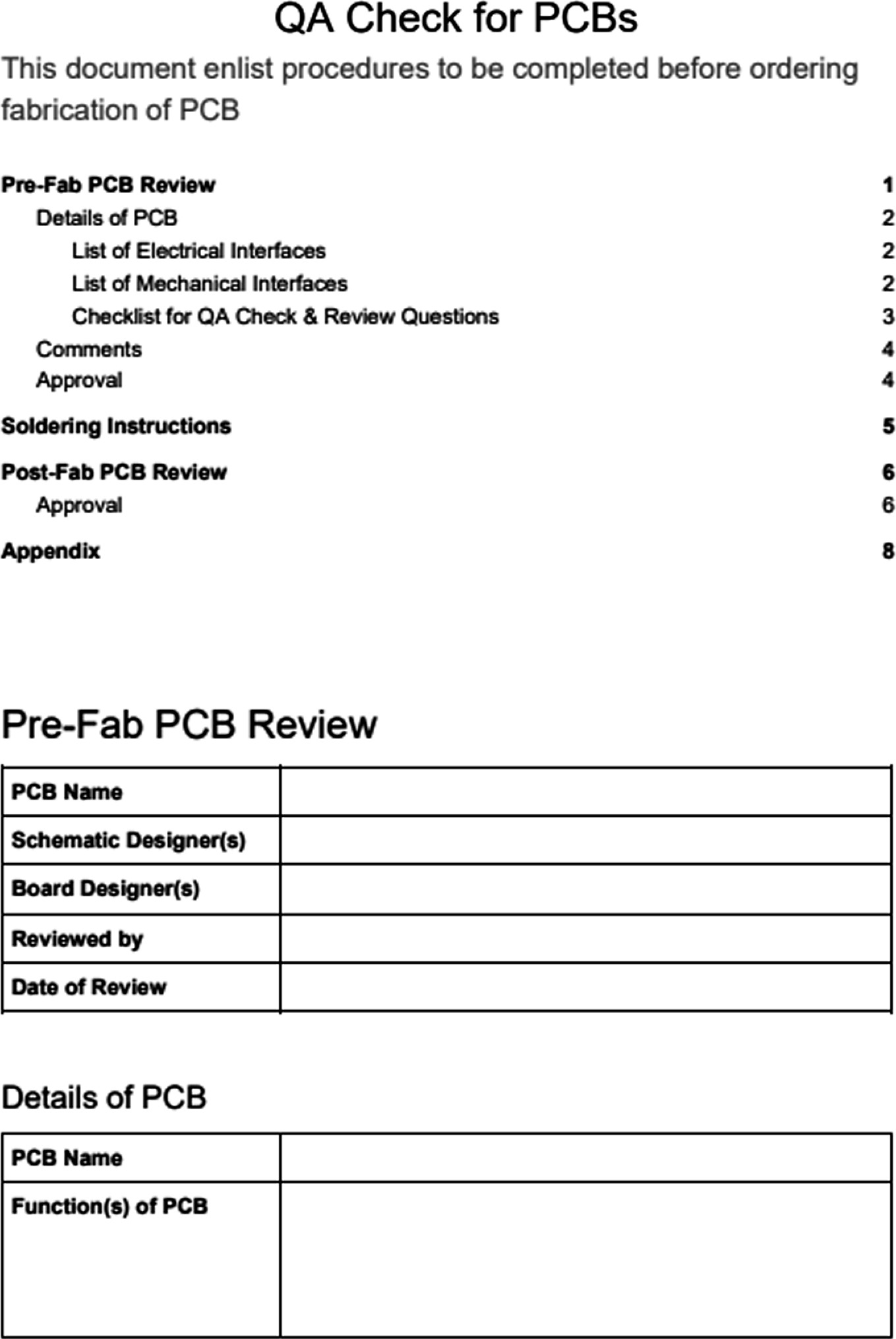

Pcb requirements stated clearly from the start.

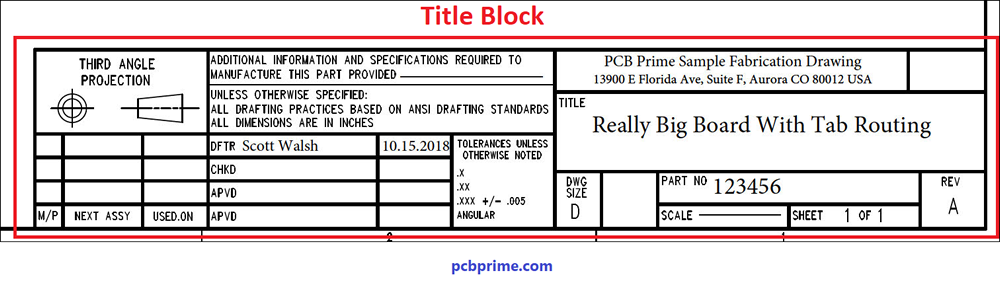

Pcb fabrication notes pdf. Assembly drawings like fabrication drawings require their own set of notes. The added benefit of this is when you export the gerber as a pdf you can easily refer to the fab notes to understand how many layers and holes your design has. This is especially important when you ve requested competitive bids from multiple suppliers. General fabrication notes for rigid boards can be gleaned from the ipc 6012 while ipc 6013 covers flex circuits.

12 along with all data files. Keep in mind that the pcb manufacturing process is mostly chemical. Minimum track width requirement is 0 2 mm and minimum spacing between tracks is 0 2 mm. This just isn t good enough if you don t have an accurate schematic then your pcb will most likely end up a mess and take you twice as long as it should.

These notes may be supplied in paper form but a gerber for. Ipc 600 is an umbrella document concerning workmanship across the board. Design a pcb stack that supports a large plane capacitance. Why your standard pcb fabrication notes needs updating.

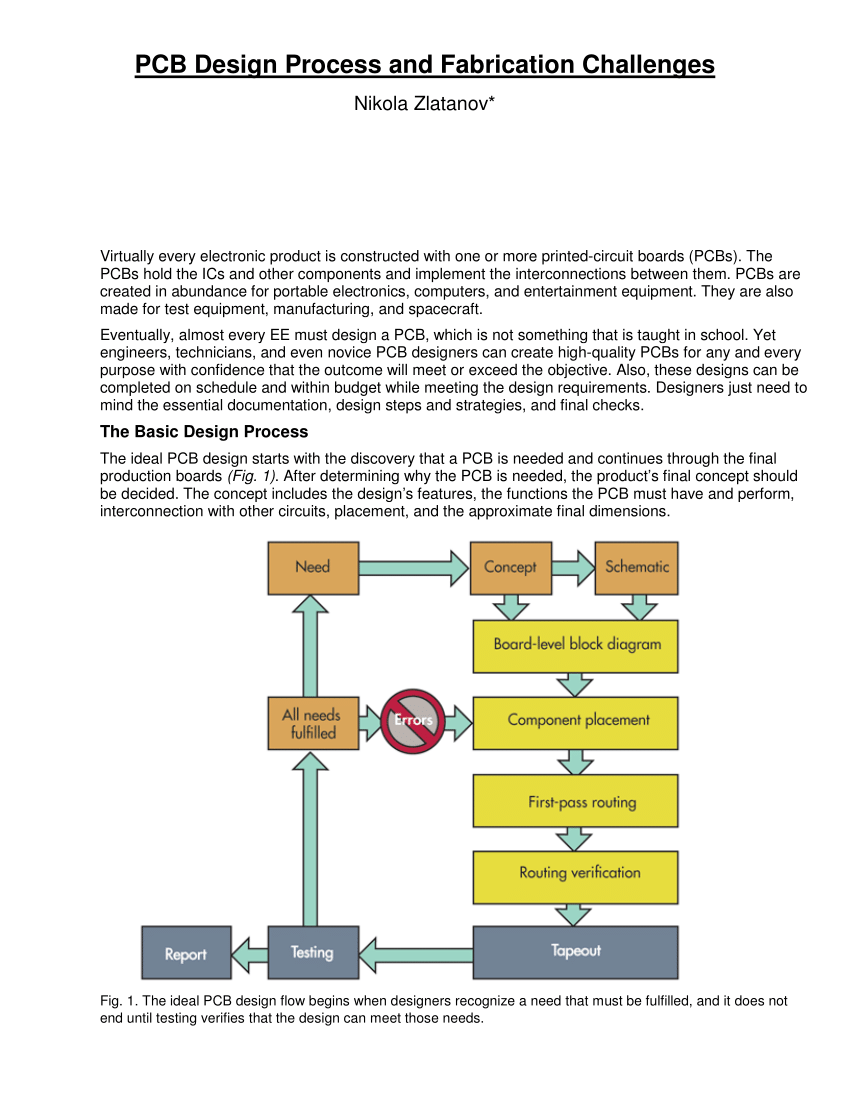

1 manufacturing panel utilization how many pcbs fit on the master panel 2 performance class ipc 6012d class 2 vs 3 3 layer count total number of required cores cores layers2 2 4 number of lamination cycles each cycle requires lam drill plate etch est 25 per lam cycle 5 design complexity and whether the requirement is standard green. People jump straight into the pcb design with nothing more than the circuit in their head or the schematic drawn on loose post it notes with no pin numbers and no order. Specify ground1 and power1 to be close in the stack separating them by 2 mils. In case the pcb design software does not include the functionality to create a fabrication drawing there are other alternatives that can work.

There s no such thing as too much detail in your assembly documentation. By correctly stating all of your pcb requirements from the beginning you can be confident that you will receive an accurate quote with a realistic delivery schedule. There are so many steps that require proper chemical. Routing loops pcb routing completion detector preserving track angles while dragging designing bottom layer layout mirror has to done just by flip and editing the board etc.

Use a basic graphic design or presentation software tool as simple as microsoft powerpoint to create the drawing and save it as a pdf file. Pcb requirements cost factors. The fabrication drawing to provide the pcb manufacturer with a clear description of the requirements and the limitations of a design the designer should supply the manufacturer with fabrication notes and a fabrication drawing figure 1 18 p. Note that stacking the power and ground plane tightly can help.